From the smallest components like a brass neutral link to the largest frameworks incorporating three-phase power circuits, electrical systems can become incredibly intricate. Each and every electrical device that allows for the flow of current requires safe and systematic distribution, which calls for the use of connectors. Regardless of whether you operate in a residential, commercial, or industrial setting, a brass neutral link enhances the performance and safety of the entire system by providing a neutral wire connection.

As a trusted Brass Neutral Link manufacturer in Jamnagar, Saryu Industries delivers high-precision, corrosion-resistant, and customizable brass neutral link solutions used across various sectors.

What is a Brass Neutral Link?

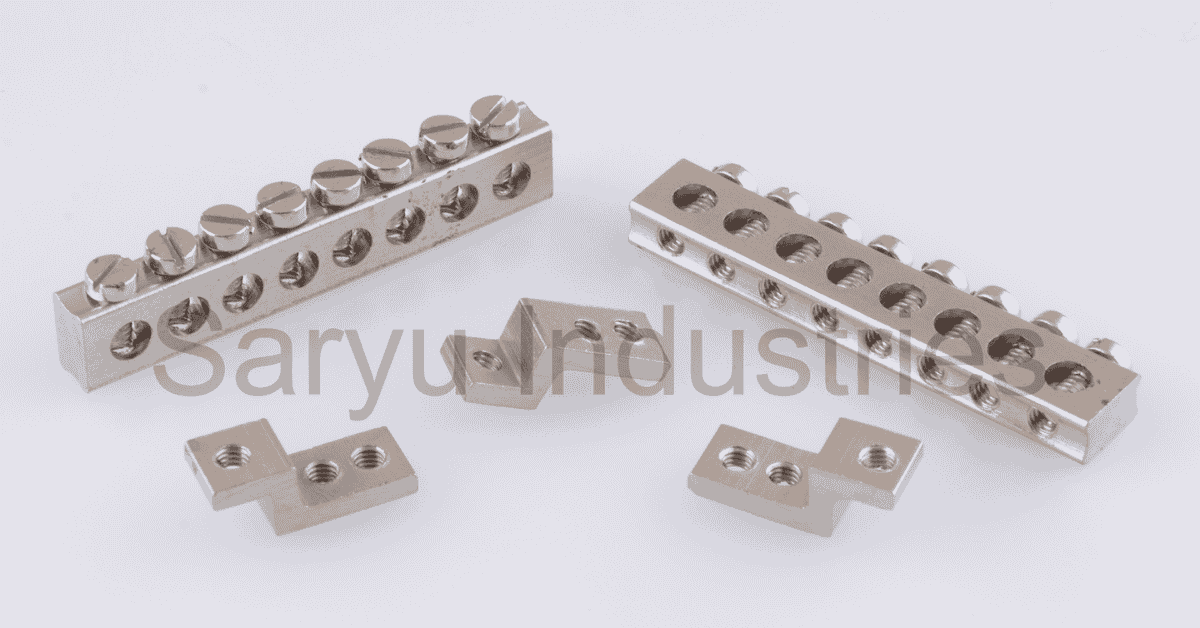

Brass Neutral Link is an electrical device that provides a common point to multiple single-phase individual circuits, offering a neutral. MCB distribution boards, power panels, and switchgear all carry these devices. To enable a balanced flow of electric current while preserving the safety of a circuit, they let current flow through.

Why Brass?

With respect to other materials, brass is preferable because it is an excellent conductor of electricity, does not get corroded easily, and possesses outstanding strength. Because the neutral link must take heavy currents without damage, it must be effective for permanent uses.

Key Features of Brass Neutral Links

Brass Rivets for Leather

Electrical and Industrial Use

Marine and Automotive Applications

Types of Brass Rivets Available

Various configurable rivets for various complex engineering and design needs:

Solid Brass Rivets

- Handles the most severe stress

- They are challenging to mess about with or harm, making them durable.

- Use these for securing parts of a structure together.

Hollow Brass Rivets

- These lightweight elements are ideal for flexible or decorative connections.

- Appeal greatly and install easily while serving a stylish purpose.

- Used in combination with various head designs, tachometer, length, and finishing touches to meet certain criteria

Countersunk Brass Rivets

- Finishing touches such as smooth surfaces are required, and these cover it all.

- Panels and housings are the ideal places to use it.

- Flush the surface; thus, the flat appears above the head.

Custom Brass Rivets

- Branded projects with custom hollow brass rivets that support steel offer clients bespoke manufacturing solutions.

Key Benefits of Brass Hollow Rivets

Brass Rivets Advantages:

Durability:

- Withstands impact, vibration, and pressure

Corrosion Resistance:

- Strong in chemicals and wet conditions

- Maintains strength in extreme environments

- Everlasting golden gloss color

- Marine and other outdoor ruses resistant

Electrical Conductivity:

- Effects current flow in porous brass assemblies

- Alleviates energy loss and heat buildup

Aesthetic Appeal:

- Ideal for wooden or antique leather exposed fasteners

- Reduces wear through tarnishing in vessels and outdoor furniture, ensuring enduring shines.

Why Manufacturer Selection Matters

Selecting the right rivets manufacturer for your components ensures they serve their intended purpose while maintaining thematic strength. A reliable, Hollow rivet supplier should offer:

- Scalable production for custom bulk or small orders

- Custom services for head type, size, and finish

- Specialist precision crafted with remarkable tolerances

- High-grade, durable brass bush material

Working with a custom brass rivets supplier gives you complete control over rivet specifications to align them with your design vision, especially for high-performance projects.

Related Hardware: Brass Bushings

Brass bushings are often paired with rivets to reduce friction in rotating or sliding parts for precise mechanical design.

Brass Bushing 1/2 x 1/4

- Carves out space for plumbing, electrical work, and machinery.

- It is known for reliability and resistance to damage.

Sourcing from Jamnagar

- Jamnagar is a hub leading in brass bush manufacturing.

- It has both customized and standard sizes with quick delivery.

Conclusion

Brass Hollow rivets are used for securing electric terminals, which is a reliable engineering and design solution and their best use. Asserting in leather goods and marine-grade installation, shrivets are notorious for their strength, elegance, and longevity. With this much variety from countersunk brass rivets to custom brass rivets, there is a solution to every problem. Selecting the right rivets manufacturer for rivets guarantees the project will be finished efficiently without any malpractice.

Looking for a fastening solution that won’t fail? Partner with a reliable brass Hollow rivets supplier; whether you’re placing bulk orders for industrial use or need designer custom rivets, rest assured that every connection will be secure, fashionable, and durable.