Brass is among the most versatile materials applied in industries such as electrical, plumbing, decorative, and precision engineering. The reason for its versatility is that it comes with an adjustable brass composition, which can be adjusted to suit particular application needs.

Knowing what is brass made of enables manufacturers and engineers to choose the best suitable brass material for toughness, conductivity, durability, and aesthetic appeal. Let’s discuss how the brass composition directly affects product functionality and performance. Electrical products such as terminals and Brass Electrical Pins are enhanced by its conductivity.

What Is Brass Made Of? Basic Chemical Structure

Brass is a mash-up of copper and zinc alloy. Switch the ratio and you suddenly have an alloy that acts totally different. Leaning toward copper gives the metal a warm glow and fights rust; stuffing in extra zinc cranks up strength and keeps edges sharp. That balance of elements decides whether the final part will be soft enough to draw or hard enough to bolt down.

Most commercial grades stay in the ballpark of 60 to 70 percent copper and 30 to 40 percent zinc, but engineers love the wiggle room. A tiny tweak can mean the difference between a decorative knob and a railway coupling, letting users dial in performance without starting from scratch.

Chemical Composition of Brass

Aside from copper and zinc, small amounts of other elements may be incorporated to control performance. Tin enhances corrosion resistance, lead improves machinability, and nickel or aluminum can provide strength and color. These secondary elements both affect the chemical composition of brass and its ability to be worked, particularly in high-precision manufacturing.

Brass Material in Global Trade

Indian manufacturers, more so in Jamnagar, have emerged as world leaders in the production of good-quality brass material. Their control over homogeneous brass composition and advanced machining has established India as a leading exporter of brass components.

Indian brass compositions capacity to provide custom alloys, rigorous quality inspections, and prompt delivery has earned them great trust in Europe, the Middle East, and North America.

Types of Brass and Their Applications

Brass isn-t a one-size-fits-all metal; it splits into types of brass based on its recipe. Know the category, and you already have a pretty good hint about where the alloy will be put to work.

Commercial Brass Types

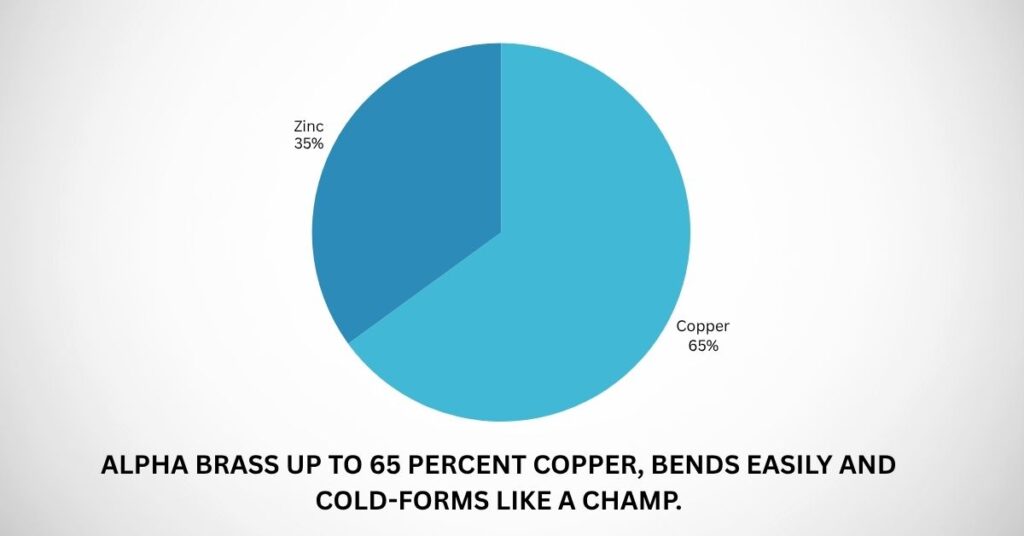

- Alpha Brass Up to 65 percent copper, bends easily and cold-forms like a champ.

- Beta Brass Caps out at 45 percent zinc, tougher stuff that handles hot work without cracking.

- Alpha-Beta Brass A mash-up of the first two, sits in almost every hardware store and most plumbing lines.

Application-Based Brass Types

- Cartridge Brass Soft, resists weathering, and turns up in things like radiators and ammo cases.

- Naval Brass Extra copper plus tin, laughs off seawater, so boats and subs depend on it.

- Free-Machining Brass Sprinkles lead throughout and lets lathes bite without breaking bits. Every types of brass brings its own set of perks, making it the go-to metal for a million jobs.

Brass Mechanical Properties Explained

Brass provides a combination of brass mechanical properties that make it useful for both decorative and industrial uses. Its strength in tension can withstand structural loading, and its ductility makes it possible to shape without destruction. Brass also possesses thermal conductivity and high corrosion resistance.

Due to these brass mechanical properties, it finds its application in everything ranging from Brass Inserts to critical valve components.

Uses of Brass Metal Across Industries

The various uses of brass metal cut across almost every industry, such as electrical, plumbing, construction, and automotive. In plumbing, it is a favorite among fittings and couplings because of its resistance to corrosion. In construction, brass is prized for its aesthetic appeal and strength.

Due to its aesthetic value and stability, brass material finds use both functionally and aesthetically.

Choosing the Right Brass Blend for Your Needs

When choosing a brass composition, keep the following in mind:

- Mechanical Stress: Will the part be tugged, bent, or baked under heat? If yes, you need an alloy that can stand the strain.

- Exposure Conditions: Is it going to sit in saltwater, sweat, or splash with harsh chemicals? Moisture and salt demand extra corrosion resistance.

- Manufacturing Method: Are you planning to machine, forge, or cast the piece? Some alloys chip clean while others gum up tools.

- Appearance: Do you want that classic gold sheen or a specific reddish tint? Finish can be as important as function for visible parts.

This knowledge guarantees your selection of brass material is compatible with performance requirements and economy. For further information, visit this useful LinkedIn article on Why Choose Brass for Pins?

Why Brass Composition Matters in Design and Manufacturing

Knowledge of brass composition is important to ensure that you select the proper alloy for the purpose intended, prevent premature failure, and maximize safety and efficiency. For instance, electrical parts need high-conductivity brass, whereas plumbing fittings require corrosion-resistant compositions.

When ordering quality brass parts, begin by matching the proper brass composition to your requirements.

Conclusion: Smart Material Choice Begins with Brass Composition

In short, brass is more than a mere ornamental metal. Brass works great almost anywhere industrial workers need dependable metal. Its blend of copper and zinc creates a mix that stands up to heat, tools, and time. Knowing what is brass made of and types of brass, the main grades on the market, and the chores each one handles lets buyers pick an alloy that won’t rust, break, or look dull when the job is done. In many shops, that sort of flexibility is worth its weight in gold-at least close to it.

The next time you’re designing, sourcing, or producing, take into account both brass metal properties and the chemical composition of brass to choose the most efficient solution.

Whether for form or function, a solid understanding of brass composition is the key to attaining reliability in whatever application.