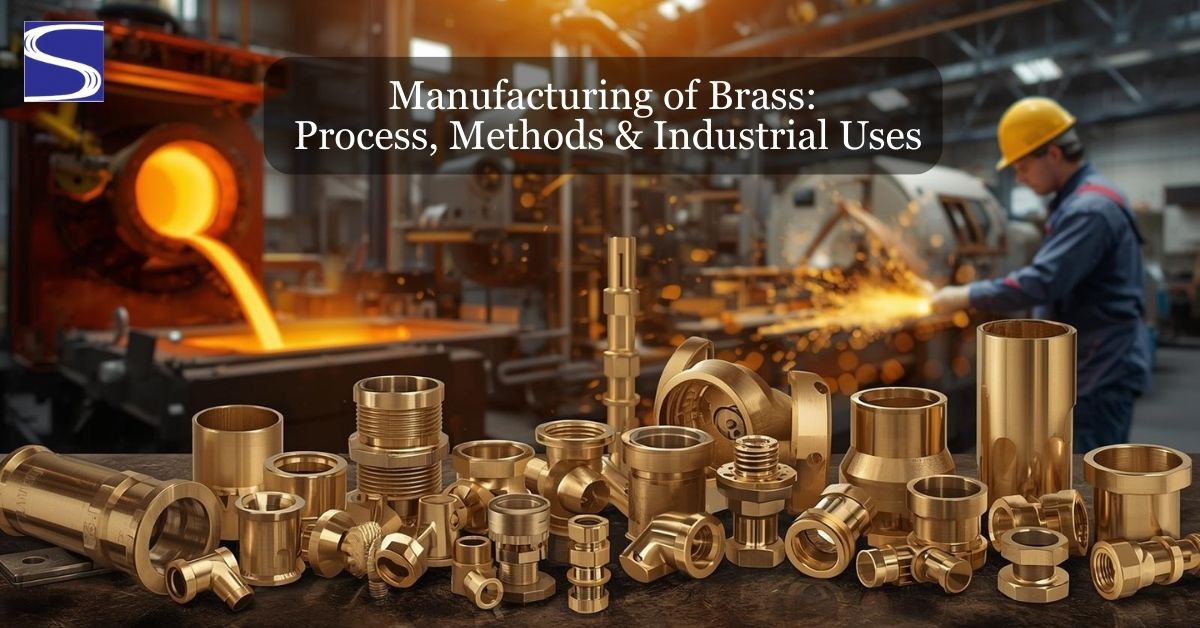

Brass is one of the most commonly used alloys in modern industries. Its manufacturing of brass is vital in all the relevant sectors like engineering, construction, electricals, plumbing, and machinery. It enjoys a great reputation among the industries to produce precision components and fittings because of its great smooth finish, durability, machinability and corrosion resistance.

The demand of the global and domestic markets has aided significant leaps in the manufacturing of brass owing to technological advancements in casting, machining and finishing. The range of industrial applications of brass is huge and it has evolved from traditional alloy preparation to modern CNC production.

What is Brass and How is Brass Formed?

The alloy, brass, is composed primarily of the two metals: copper and zinc. Depending on which of the two metals, copper or zinc, which is used in the alloy, this determines the strength of the alloy, its color, and, in general, the final properties of the brass alloy formed. Brass provides excellent performance to many industries because it is affordable.

So, how is brass formed? In the alloy creation process, the first thing done is the selection of quality grade copper and zinc. The final process involves the heating and melting of both metals so that they blend together. The final step involves casting the molten alloy to take the shape of desired loads, which can either be rods, sheets, or wires.

The specific grades and mechanical properties of brass needed for particular uses make it necessary for industries to understand how is brass formed.

Step-by-Step Manufacturing Process of Brass

Modern technology has improved the accuracy of the manufacturing process of brass. For accuracy and consistency, modern brass manufacturing employs cutting-edge machinery.

Copper: The Foundation1. Selection of Raw Materials of Brass

The first step in manufacturing of brass is the selection of quality grades of copper and zinc. The strength and quality of any brass alloy, as well as the alloy’s conductivity and resistance, are determined by the purity and proportion of the metals.

2. Melting and Alloy Formation

A quality gaseous furnace is used to melt copper, and then zinc in a controlled manner is used to blend with the copper, producing a brass alloy. This is one of the critical stages in the manufacturing of brass on which many industries are dependent.

3. Casting Process

In casting, the alloy is cooled and then cut. It is then placed in molds to shape the brass into billets and ingots or particular components. Casting is one of the major processes in the manufacturing of brass as it allows for the creation of standard and complex designs.

4. Rolling and Extrusion

In the next step, the brass is cut into sheets, pipes, or rods. This is done through extrusion or rolling. It then strengthens the structure of the alloy. It also makes the brass suitable for machining.

5. CNC Machining and Turning

Brass fittings, inserts, electrical terminals, and connectors are often manufactured using a method known as precision machining, which is one of the most widely used techniques for machining brass. It enables the attainment of great accuracy and a smooth finish.

6. Surface Finishing

Finishing techniques, such as coating, buffing, electroplating and polishing are used as an enhancement for aesthetic purposes, as well as an improvement for the corrosion-resistant qualities of the metal.

Manufacturing brass components involves an entire process to ensure that the parts produced are of high quality and meet the standards of the industry.

Different Methods Used in Brass Manufacturing

In modern manufacturing of brass, different manufacturing processes can vary according to the different products and their end-use specifications.

Casting-Based Brass Manufacturing

Once the alloy is made, the next step is pouring the alloy into the molds designed to produce the brass billets, ingots or other components. The casting is a major process in brass manufacturing as it makes the manufacturing of both simple and complex components possible.

Machining-Based Brass Manufacturing

For precision parts in the industry, machining is the most popular method used by brass manufacturers. CNC turning, drilling, threading, and milling are no doubt the most accurate in the automotive and electrical industries.

Hot and Cold Working Techniques

Hot and cold working are two different processes that improve different aspects. While hot working improves flexibility, cold working increases strength. These processes are used to produce brass rods and sheets that are durable, and are, in fact, very.

The importance of choosing the right method should not be underestimated. It ensures high-quality manufacturing of brass and satisfies the different industrial needs.

Brass Manufacturing in India: Industry Expansion

The growth of brass manufacturing in India has been remarkable over the last few decades. India has become one of the world’s leading brass component hubs, supplying brass components to both internal and global markets.

The demand for electrical fittings, plumbing parts, automotive components, and industrial machinery has increased the scope of brass manufacturing in India. Because of CNC machining and the production of hi-fidelity mare alloys, Indian manufacturers have been able to win global prestige.

To explore detailed industry insights, visit: Brass Manufacturing in India

Supply chain production capabilities for brass manufacturers are improving India’s position internationally.

Brass Manufacturing in Jamnagar: The Brass Capital

When analyzing brass manufacturing in Jamnagar, one must consider the potential of Jamnagar, Gujarat, being the “Brass City of India” due to the incredible number of brass industries in the region. It is imperative to recognize Jamnagar’s status as Asia’s largest brass component manufacturing cluster.

The region manufactures the following brass components:

- Electrical terminals

- Precision inserts

- Plumbing fittings

- Automotive brass components

- Industrial hardware

The brass manufacturing in Jamnagar is in a desirable position to supply the rest of the nation, due to its combination of skilled labor, sophisticated machining, and export-driven focus.

For trusted suppliers, explore: Brass Manufacturers in Jamnagar

Due to its large-scale production capacity, the brass manufacturing in Jamnagar is pivotal to India’s brass exports.

Industrial Uses of Brass in Modern Applications

The manufacturing of brass provides multiple industries with the benefits of durability, conductivity, and excellent machinability.

- Electrical and Electronics Industry: Brass is used in the manufacturing of electrical components because of its ability to conduct and resist corrosion, making it effective for terminals, connectors, switches, and earthing components.

- Plumbing and Sanitary Fittings: Brass is often used in water plumbing systems because it does not corrode, and makes for effective valves, piping, and nozzles.

- Automotive and Mechanical Industries: Brass components that are precisely machined can be found in engines, radiators, sensors, and entire braking systems.

- Construction & Ornamental Hardware: Brass locks, handles, and architectural fittings, as well as hinges, provide a construction element that is strong and aesthetically pleasing.

The above-mentioned numerous uses of brass in various industries, demonstrates the necessity of brass manufacturing in the construction of industries.

Advantages of Modern Brass Engineering

The primary focus of modern engineering in brass is to improve the quality, speed, and consistency of brass production. The introduction of new automated casting and advanced CNC machining processes have transformed brass engineering to be efficient and highly scalable.

Key advantages include:

- Excellent accuracy of dimensions of brass products

- Good finish of brass products

- Good resistance to corrosion

- Good mechanical properties to cost ratio

- Good tailoring to manufacturer specifications

For more about innovation and expertise, see: Advantage in Brass Engineering

These innovations are shaping the future of manufacturing of brass globally.

Conclusion

The manufacturing of brass is a complex and highly specialized industrial process including alloy formation, secondary brass casting, machining, and finishing. Knowing how is brass formed, the various brass manufacturing processes, and the role of brass manufacturing in India growing helps industries in the sourcing process.

As the global brass component industry is led by India and specifically Jamnagar for the brass manufacturing production hubs, the reliable brass manufacturers will be in demand as the industries evolve, driving innovation and industrial progress.